Global manufacturing is entering a new era, shaped by shifting trade policies, technological advancements, and the urgent need...

Read More »Machine Vision and Optical Technologies

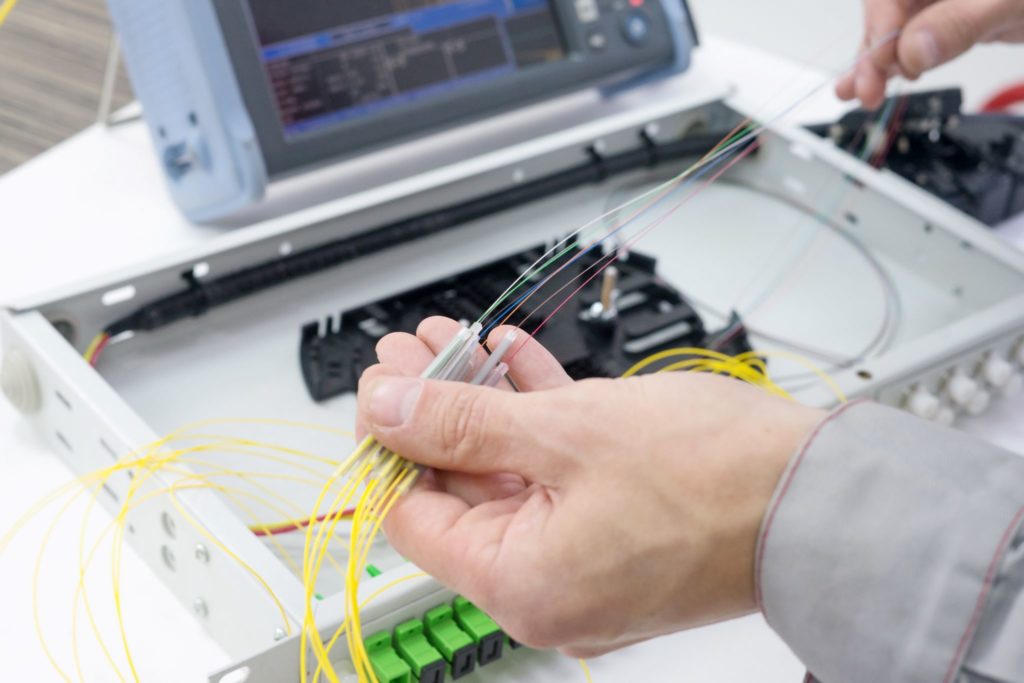

Machine vision and optical technologies are rapidly increasing in sophistication and deployment. From smart factories to surgical theatres, Nortech Systems is at the forefront of innovation in this field. Our customizable family of small form-factor hybrid Active Optical Cable assemblies, performing E-O/O-E within a single cable, are solving next-generation multi-function cable challenges now.

Fiber optic technology is revolutionizing data transfer applications, significantly enhancing performance in countless applications across multiple industries. As the burgeoning field of optical communication grows, so will its applications, leading us into a new era of data transfer and networking.