Customized Aerospace & Defense Interconnect Solutions

Termination and Assembly

Benefit from advanced cable and harness assembly and termination processes, like high-quality crimping, soldering, and shield termination. Quality control and compliance with industry standards are guaranteed. Services also include printing, marking, wire stripping, and cutting.

Nortech’s Cable Terminations and Assemblies offers a sophisticated range of processes and equipment for electronics engineers and defense experts. These tools offer precision, durability, and efficiency for complex cable and harness assemblies.

Processes and Equipment

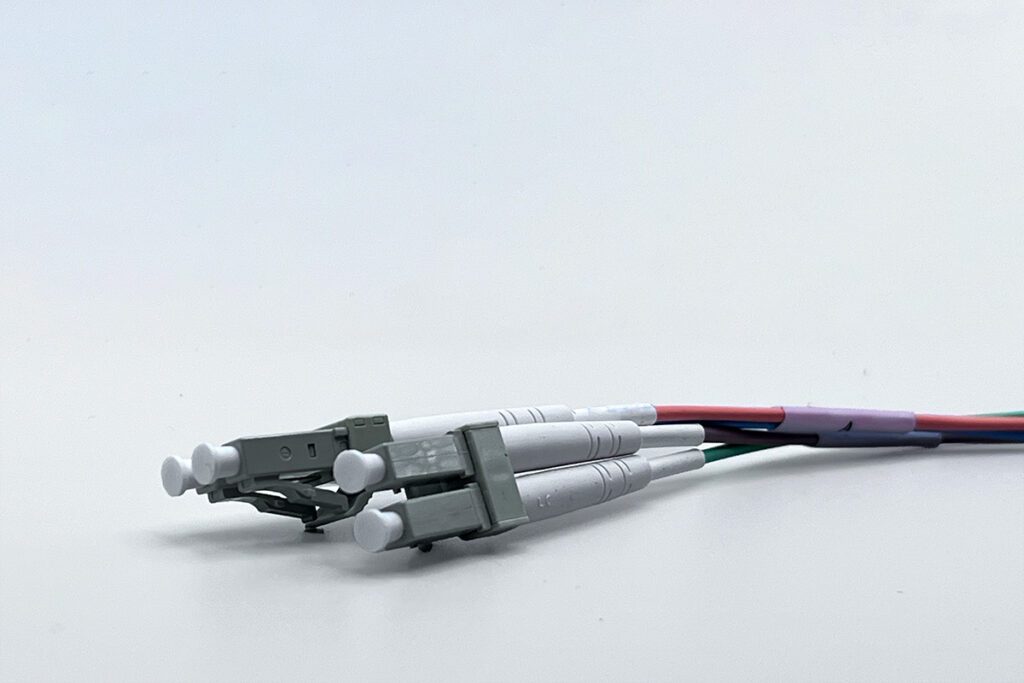

Nortech is fully equipped including trained personnel to assemble and terminate cable and harness assemblies of all types. We are work with all connector types from 4/0 ground power connectors to nano size.

Markers and Labels

Shrinkable tubing markers in continuous lengths to the requirements of SAE AS5942. Ladder style shrink tubing markers capability. Continuous roll wraparound markers. Label printing on the material of your choice.

Assembly and Part Marking

- Pad printing to produce high quality ink markings on flat and curved surfaces. Epoxy ink per A-A-56032 or the material of your choice.

- Hand ink stamping

- Dot peen or stamp markings on metal items

Wire Stripping and Cutting

Nortech utilizes high quality automated and manual equipment to produce nick and scrape free wire strips and cuts.

- Schleuniger automated cut, strip, and coil equipment

- Automatic and semi-automatic wire strippers

- Die type hand strippers

- Thermal strippers

Jacket Stripping

Jacket stripping is performed using semi-automatic equipment, including non-round jackets, to preclude damage to shields or insulations that may be encountered when using hand tools.

Crimping

High quality crimps are obtained through crimp tool selection and calibration.

- Operators are trained to IPC-A-620 requirements.

- Crimp tools are selected to meet requirements of MIL-DTL-22520 or connector manufacturer’s specifications

- Air or hydraulic assisted crimp tools are used where possible

- Termination presses and applicators for strip form contacts are controlled to manufacturer’s specifications including crimp height

Soldering

- All soldering is performed by IPC-A-610 trained personnel.

- Soldering to 32 AWG regularly performed

- Dip solder capability such as for ground straps

- Torch or high output 1000 Watt iron capability

Shield Termination

Nortech offers multiple ways to attach overall braided shields to backshells.

- All shields are terminated 360 degrees utilizing copper foil tape if necessary to fill gaps in expanded braids.

- Soldering overall shields 360 degrees around backshells provided by Nortech provides the ultimate in low resistance and high reliability. Utilizing Nortech backshells with solder terminations is lowest cost, low profile, and lightweight.

- Termination bands made of stainless steel are a good option when soldering is not desired due to backshell or braid materials such as stainless steel or Kevlar®. Bands in multiple widths are suggested in accordance with SAE AS85049/128.

- Crimp rings are available as custom or catalog items for shield terminations. Crimp rings can be compressed 360 degrees or in a hex pattern.

Torque Assembly

Assembly of backshells, screws, and threaded components with or without adhesives is achieved utilizing calibrated torque tools. Nortech utilizes off the shelf connector mates and has the capability to manufacture custom connector mates for complex assembly operations.

Circuit Boards

Nortech incorporates active and passive components and printed circuit assemblies into cable assemblies. These items can be accessible through custom housings and backshells or securely sealed and isolated from shock within moldings.

ESD Control

Electro-static discharge sensitive items and assemblies are processed in controlled areas with monitoring per industry standards to assure susceptible component reliability.

Harness Boards and Fixtures

Fixtures are utilized to the maximum extent possible to error proof assembly. Most fixtures are solid modeled and 3D printed to match exact profiles. Harness boards are designed and manufactured combining 3D printed fixturing into boards to provide precise dimensional control. All fixturing is manufactured in house to reduce lead time and cost.