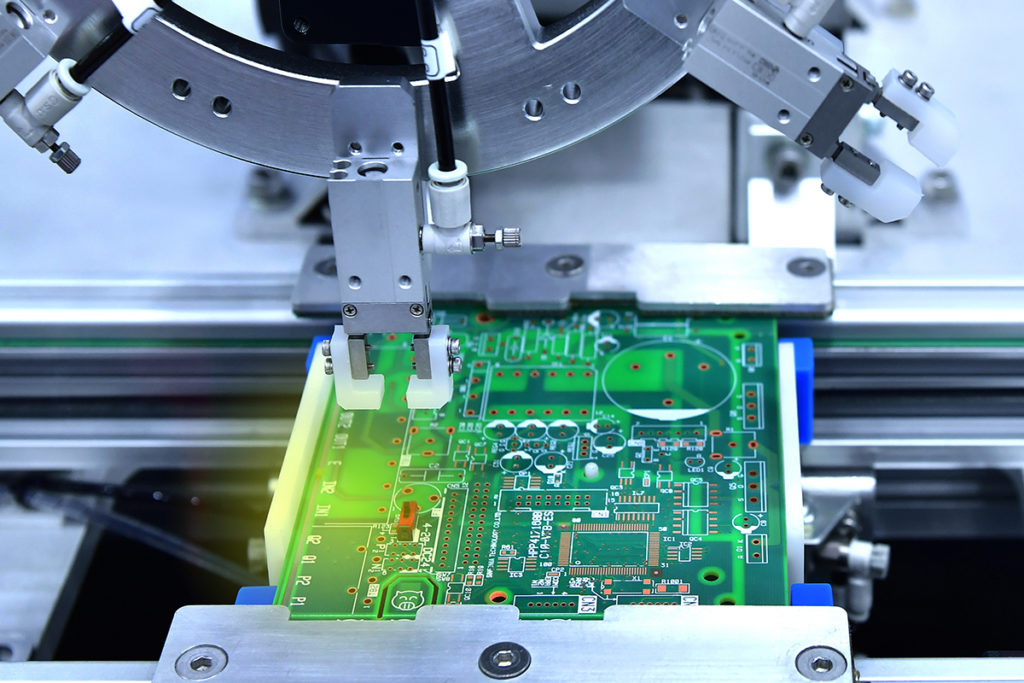

In today’s fast-paced electronics manufacturing landscape, optimizing test processes is paramount to achieving higher yields, reducing costs, and...

Read More »Ensuring Excellence in

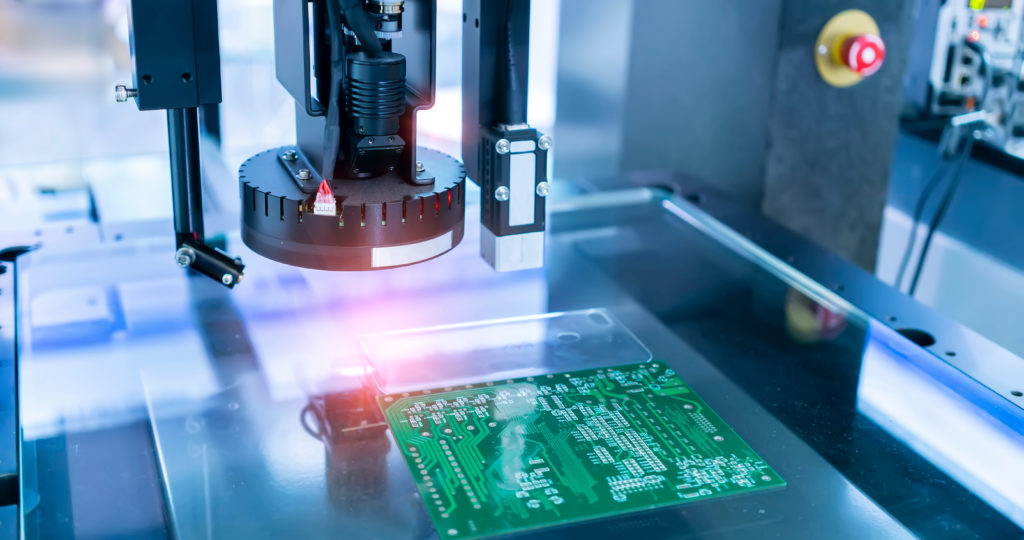

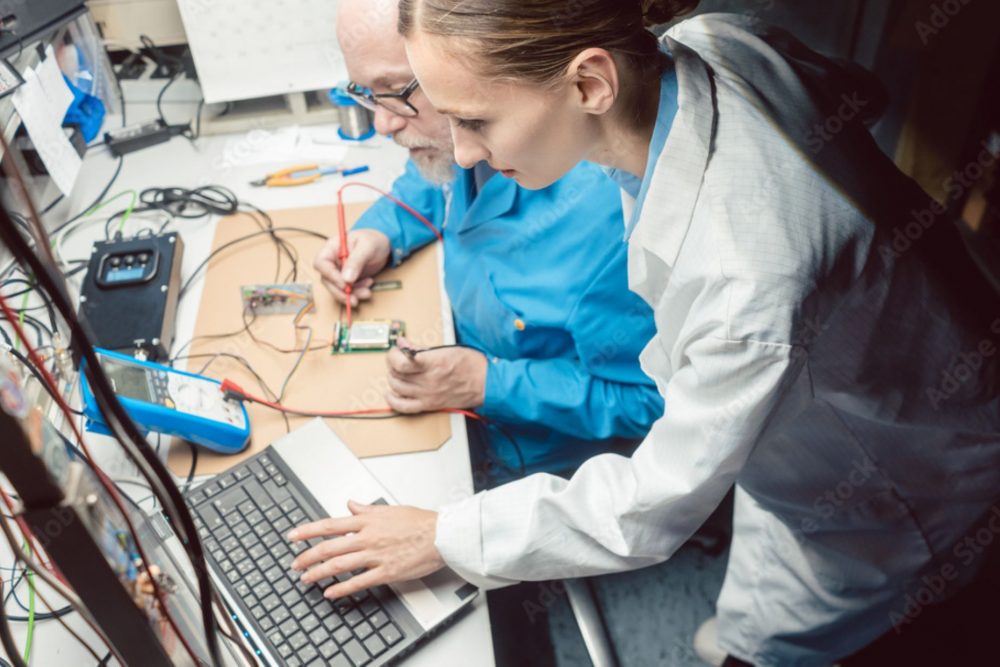

PCB Assemblies for Aerospace and Defense Industries

At Nortech, we understand the complexities of mission-critical aerospace and defense applications, where components face harsh environments. Our dedication to engineering and manufacturing excellence ensures high-quality products and services tailored to our customers’ unique needs. We ensure reliable performance under demanding conditions, while helping safeguard vital assets like aircraft, military equipment, marine vessels, and satellites.