Global manufacturing is entering a new era, shaped by shifting trade policies, technological advancements, and the urgent need...

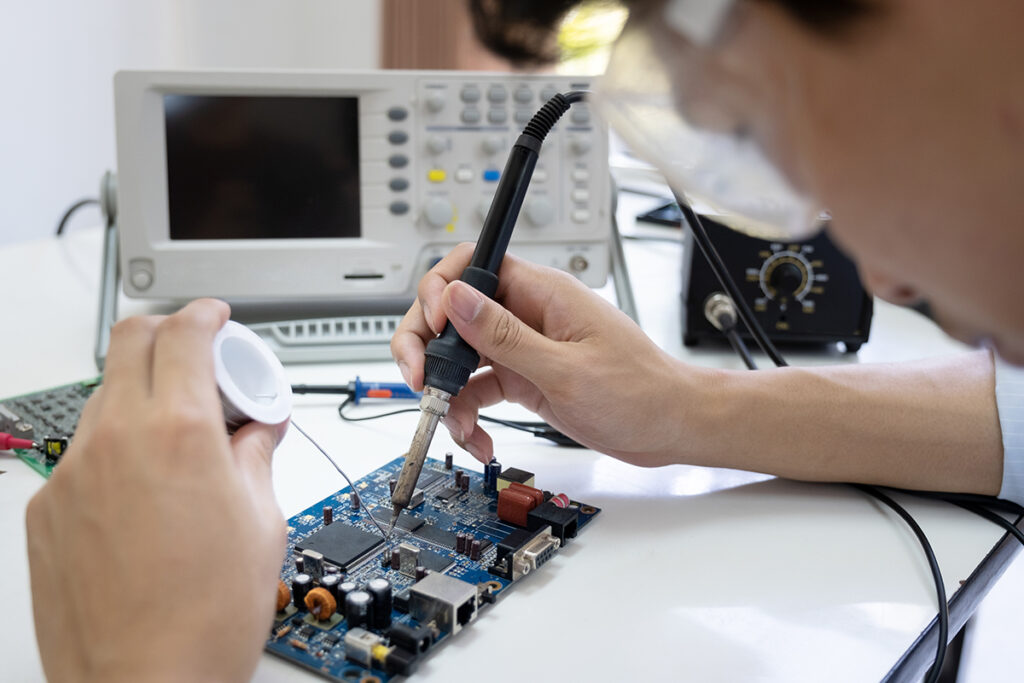

Read More »At Nortech, we combine PCB design expertise and advanced testing capabilities to address challenges in fit, cost, performance, and reliability. Our commitment to PCB design and testing ensures that every product meets the strict regulatory requirements of the medical device industry, delivering unparalleled quality and compliance.

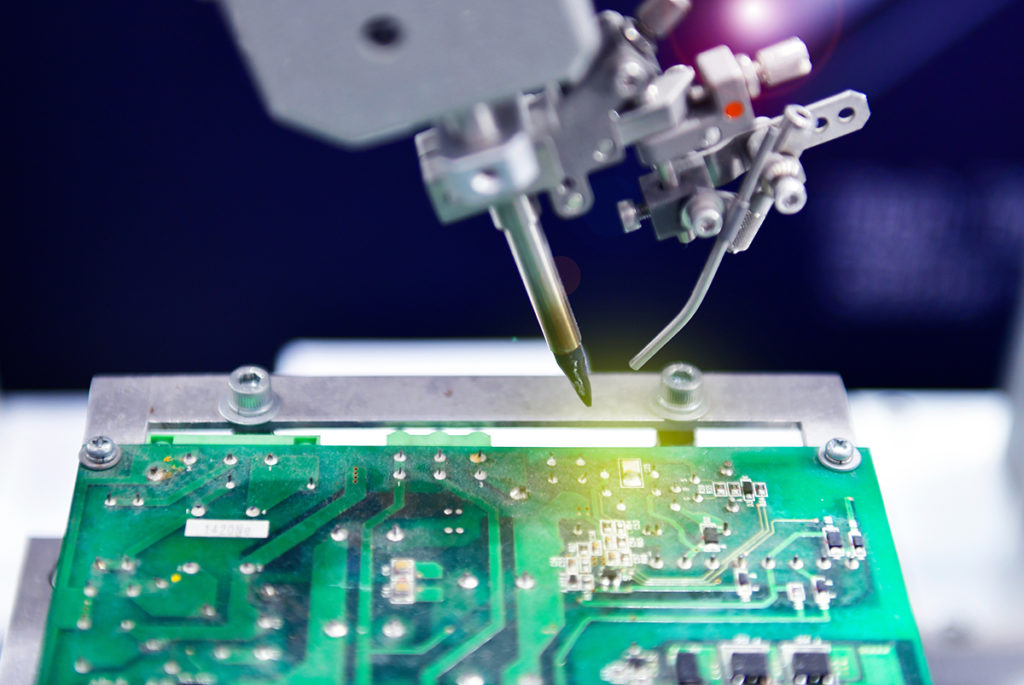

When it comes to testing medical PCBAs, Nortech provides two outstanding solutions: the ATE Checksum Dual-Purpose Tester and the SPEA 4060M Flying Probe Tester. Both tools are engineered to meet the specific testing needs of the medical industry, ensuring efficiency and accuracy in the quality assurance process.

The ATE Checksum tester is an excellent choice for low to mid-volume medical PCBA products. Its unique design combines In-Circuit Testing (ICT) and functional testing on a single platform, streamlining operations and improving test coverage and accuracy. With custom-built fixtures supporting over 600 test points, this tester achieves testing capabilities exceeding 95%, crucial for upholding the high standards of the medical sector. Additionally, its average test time of just two minutes makes it ideal for high-throughput environments. Its wide range of high-precision measurement devices and programmable power supplies highlights its versatility and precision.

In contrast, the SPEA 4060M Flying Probe Tester is the perfect solution for rapid prototyping. A standout feature is its capability to perform tests without fixturing, making it ideal for quick-turnaround projects. Although its average test time of six to eight minutes

is slightly longer than the ATE Checksum, it still delivers efficient testing for in-house needs.

Explore best practices for prototyping and testing PCB boards in the medical field. Discover how Nortech’s cutting-edge technology and meticulous quality standards can enhance the reliability and performance of your crucial medical devices, ultimately improving patient care and outcomes. Stay informed about the evolving landscape of medical technology and the vital role PCBAs play in shaping it.

Our client, a well-known surgical and medical device company, recently came to us with a product development issue. In this recent case study, we highlight the transformative journey of a custom Bluetooth console redesign, showcasing the critical role that communication and teamwork played in overcoming PCB design complexities. Discover how strategic collaboration can significantly enhance the development of medical devices. Click here to learn more about the essential strategies driving success in the medical device industry.

From life-saving medical devices to complex industrial equipment, Printed Circuit Board Assemblies (PCBAs) are essential components of modern technology. As designs become increasingly intricate and space-constrained, prototyping has become an indispensable first step in creating functional and manufacturable products. PCBA manufacturers are dedicated to reducing errors. The key to delivering high-quality PCBAs lies in the understanding of common mistakes and some techniques to avoid them. Neglecting proper precautions can compromise the performance of the final product. Let’s explore how PCBA prototyping can bring your vision to life.

Nortech System’s Custom Test Fixtures are expertly designed for each assembly to ensure top performance and reliability. By standardizing the interface across testing systems, we guarantee a consistent and efficient testing process. Our validated software and fixtures are engineered to detect assembly defects and handle high-volume testing with accuracy.

Our fixtures support both In-Circuit and Functional tests, seamlessly integrating these into a single unit. Test Result Data Logging captures pass/fail criteria and provides customizable formats to meet your specific needs. Engineered to endure up to 100,000 cycles, our fixtures require minimal maintenance, typically limited to pin and external cable replacements. To avoid software mismatches, each fixture comes with a unique signature. All our fixtures are manufactured in-house, ensuring short lead times and maintaining the highest quality standards.

Global manufacturing is entering a new era, shaped by shifting trade policies, technological advancements, and the urgent need...

Read More »The Role of AS9100 Certification in Quality-Driven Approach When reliability and safety are non-negotiable, quality management must take...

Read More »Cable assemblies are key components across industries, from medical, aerospace to military applications. Their reliability and protection from...

Read More »Since 2023, Nortech has proudly partnered with Neighborhood Forest to bring trees to communities and children across the...

Read More »

Nortech Systems is a leading provider of design and manufacturing solutions for complex electromedical devices, electromechanical systems, assemblies, and components. Its manufacturing and supply chain capabilities are vertically integrated around wire, cable, and interconnect assemblies, printed circuit board assemblies, as well as system-level assembly, integration, and final test. Headquartered in Maple Grove, Minn., Nortech currently has six manufacturing locations and design centers across the U.S., Latin America, and Asia. Nortech Systems is traded on the NASDAQ Stock Market under the symbol NSYS.