In today’s fast-paced electronics manufacturing landscape, optimizing test processes is paramount to achieving higher yields, reducing costs, and...

Read More »Industrial Engineering and Design

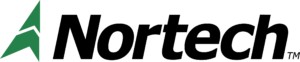

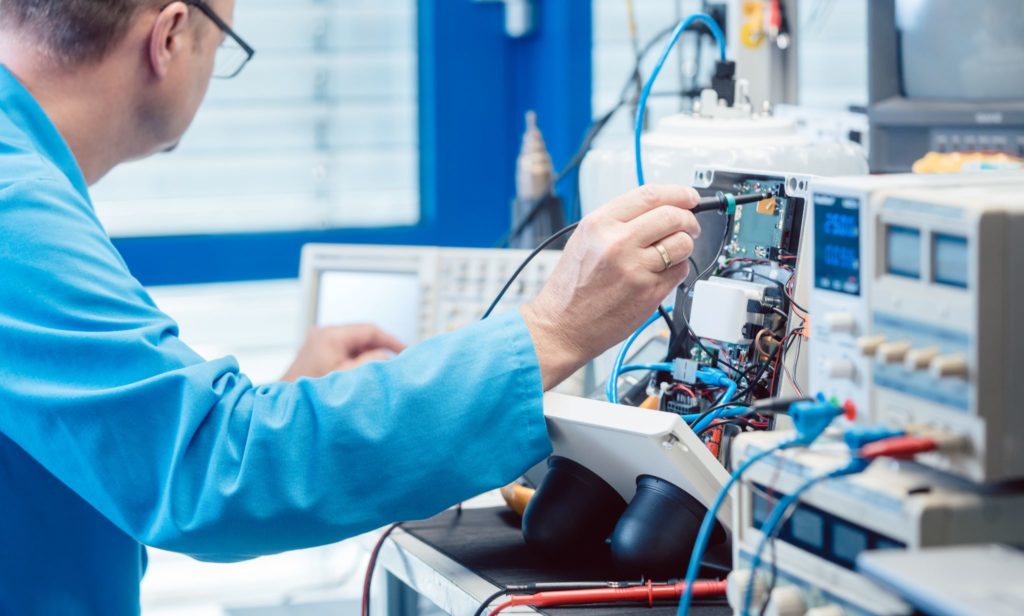

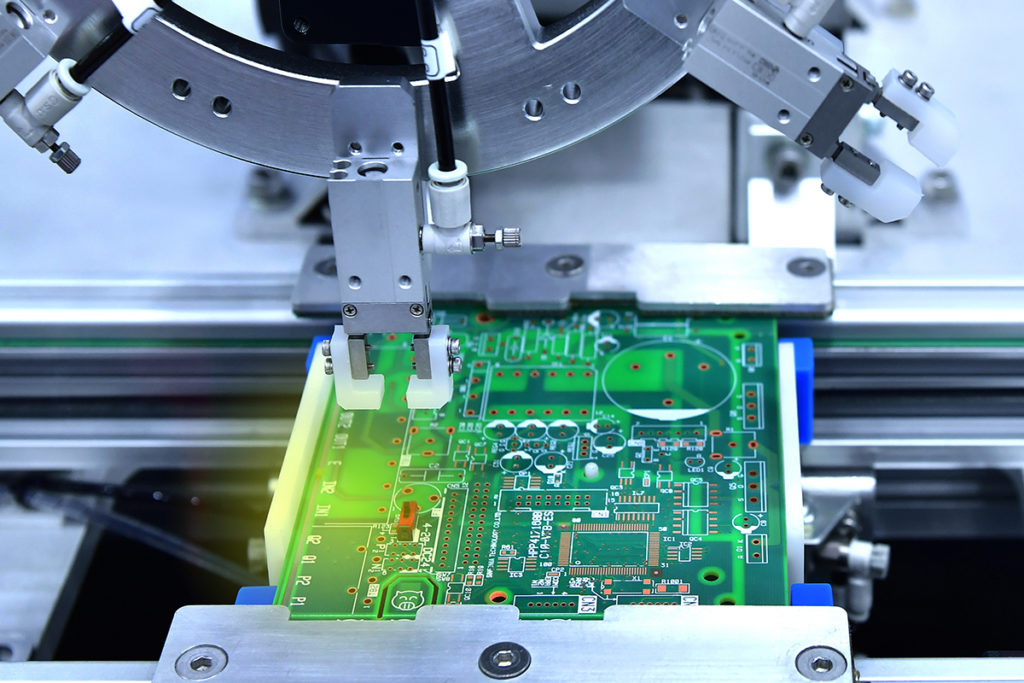

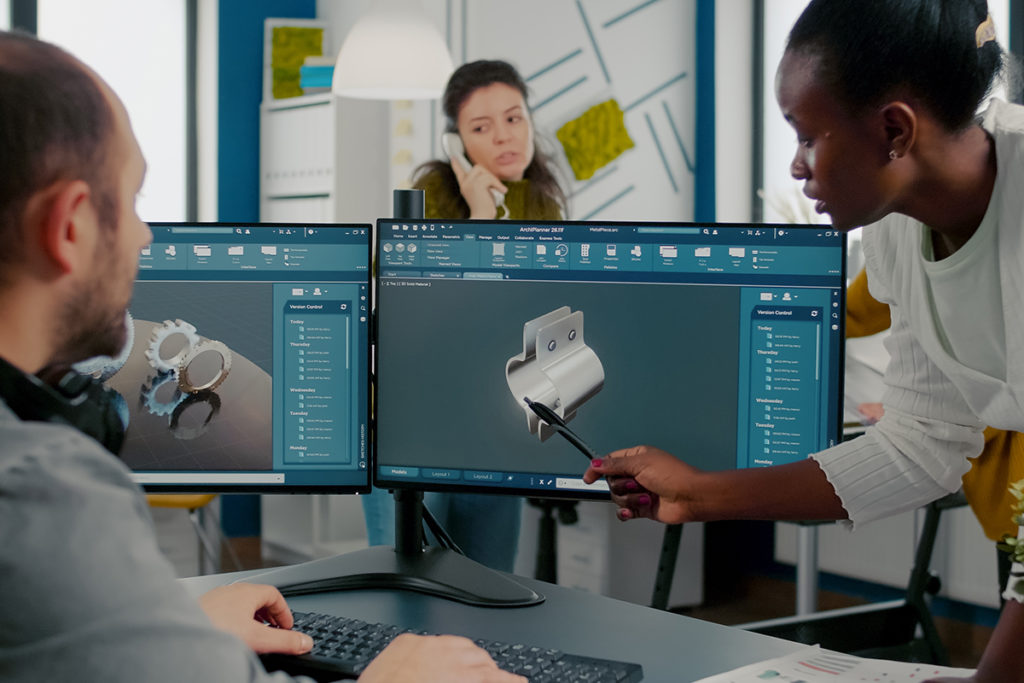

At Nortech, we offer a comprehensive range of engineering and design services for the industrial electronics market. We are a single point of contact for the entire product lifecycle, from concept development and feasibility to production, serviceability, and disposal. Our team includes experts in CAD and mechanical, electrical, and software engineering, providing a complete range of services to support your project needs.

By collaborating with us early in the design process, we offer valuable insights that can enhance product performance and ensure that the final product meets the needs of your end users. Let us help you work through the complex electronics production process, delivering solutions that drive operational efficiency and enhance the user experience.