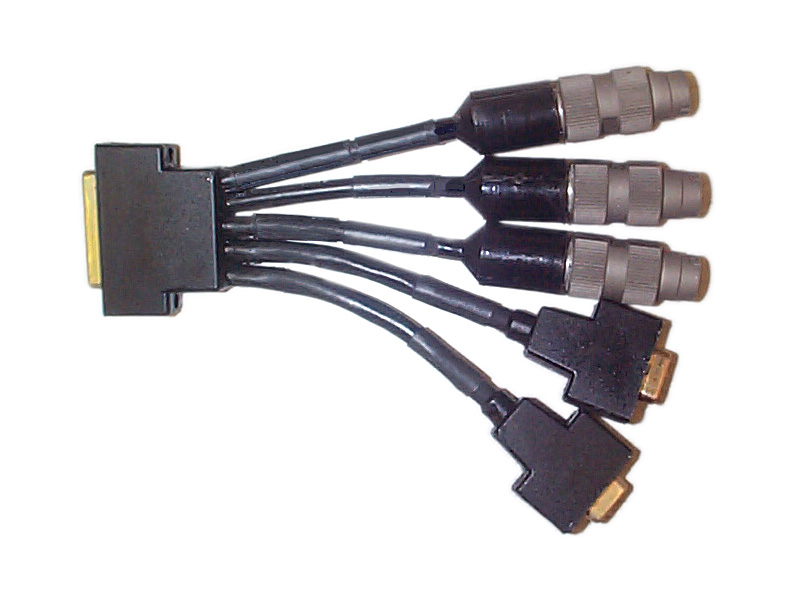

We produce molded cable assemblies here at Nortech, at our Blue Earth facility in southern Minnesota. These cables are used mainly for ruggedized aerospace and defense applications. We understand the need for the reliability and sensibility of a molded cable design and want to help. Which is why we provide the vital protection your products need to keep performing at the highest levels.

The molded cable construction process carefully selects materials, tooling types, and assembly techniques to assure top protection. Molded cable assemblies provide various advantages for reliability and cost reduction.

Molding provides additional pull strength and prevents damage at flex points. Molded assemblies offer superior water resistance, abrasion protection, strain relief effectiveness, customizable fits for tight spaces with the ability to exit and enter connectors at any angle, and exceptional aesthetics. Molded cables do not pull out or break apart when in contact with the cold or age, so replacement needs, and costs go down. These assemblies are sealed for life saving you time and money.

At Nortech, our dedicated employees offer you excellence from start to finish at every step. We provide multiple ways to create molded assembly cables, each with their own benefits. We understand that this process can seem intimidating, but we are here to help. Contact us today to get started on a project.

The casted two-part process provides impressive sealing properties as the materials chemically bond to the backshells and cable jackets. These materials are chemically cured and will not melt or deform with temperature. These materials can be economically used in low quantities and can scale up to high amounts using inexpensive tooling. Materials used include polyurethane, silicone and epoxy.

Rubber (elastomer) transfer molding provides extra dependability. Using uncured rubber, which is pushed into the mold and cured with pressure, temperature and time. Rubber cables are designed to be molded into rubber jackets (e.g., EPDM to EPDM). Materials used include polychloroprene, ethylene, and propylene diene monomer.

Injection-molded cables using thermoplastics provide injection molded cables, which help enhance the aesthetics, including superior detailing and surface texturing. With using primers, thermoplastics can be bonded to other thermoplastics and metals. Injection molding is ideal for high volume production run rates. Materials used include thermoplastic polyurethane and santopren.

We offer two methods to tool for molded cable assemblies. For most cases, we use traditional metallic-based tools, which would be aluminum and steel for high volume designs. These tools are simple to design and inexpensive to manufacture.

At Nortech, we are proud of the products we make and our ability to support some of the world’s most advanced and demanding applications. From stealth fighters to tactical communication systems, we are ready to help. Our continued attention to detail from beginning to end makes Nortech Systems one of America’s most respected and trusted cable manufacturers. Our product quality is unsurpassed, and we maintain a quality system that meets ISO-9001 and AS-9100 requirements.

We will meet any of your production or specification needs. Just as important, our customer service is involved in each step of the manufacturing process, ensuring we will be there to answer any questions you have. We thrive on helping our customers succeed.