Choosing the right Electronics Manufacturing Services (EMS) partner is a critical decision for any company wanting to outsource the manufacturing of cables, PCBAs, and integrated devices. It is more beneficial today than any other time in our industrial history to outsource manufacturing. Faced with limited resources, many companies find it is no longer the best strategy to manage all manufacturing in-house, and instead focus skilled teams on the value chain. Outsourcing items such as PCBAs, cables, and other components can positively impact the core details of a business operation, from product development to quality assurance and logistics.

Trusting a specialized manufacturer allows access to the latest tools, robust processes, and production to maximize efficiency in design and testing. Taking the risk of selecting a partner unfit for business requirements can lead to delays, cost overruns, and quality problems. Companies who partner with experts in manufacturing can achieve quicker speed to market compared to businesses using only in-house resources. Like any good alliance, you should choose a trustworthy partner to meet your demands for the long haul.

There are factors to consider when choosing an EMS partner, including:

- Experiences: The EMS partner you choose should have experience in manufacturing the type of products you need. Consider the market segments your EMS partner specializes in. Nortech’s area of expertise is in medical, industrial, defense, and aerospace.

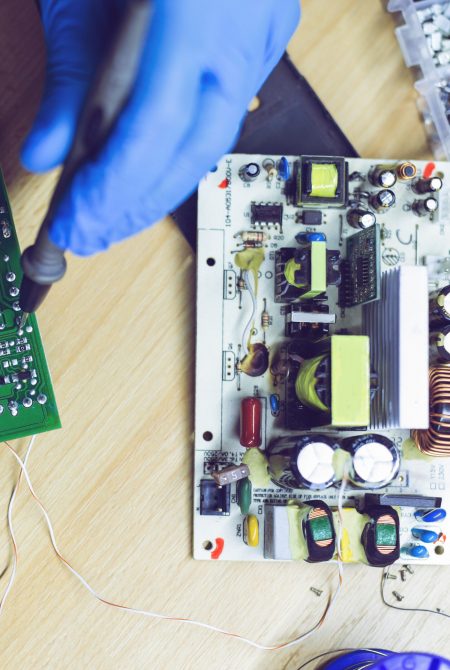

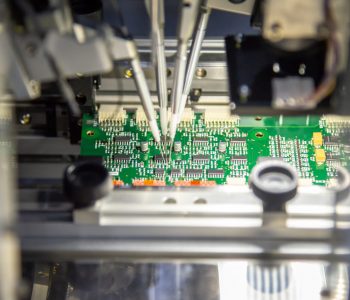

- Capabilities: The EMS partner you choose should have the capabilities to meet your specific needs. This includes having the right equipment, facilities, and personnel. An EMS partner whose capabilities support extremely high volumes and little customization may be a fit for some projects, however, a partner with capabilities for highly customized projects may fit your needs much better.

- Quality: The EMS partner you choose should have a strong commitment to quality and a flexible and robust quality management system (QMS) in place. Their QMS should include a corrective action process, which helps to identify the root causes of problems and institutes actions to prevent recurrences.

Look for certification. If the manufacturer is ISO 13845, AS1900, and ISO 9001 certified, there is a robust quality management system in place.

- Service: The EMS partner you choose should provide you with excellent service. This includes being responsive to your needs, providing you with regular updates, and resolving any problems quickly and efficiently.

- This also means their employees are trained in their content. At Nortech our employees are trained appropriately on policies, procedures, and work instructions relevant to their jobs and project. The manufacturer you choose should also be aware of the importance of quality in the organization with documented proof per certification standards.

Once you have considered all factors, you can start to narrow down your list of potential EMS partners.

If possible, visit the EMS partner’s facilities to see their operations and meet their teams in person. The partner you choose should be based on your specific project goals. It is important to remember choosing an EMS partner is a long-term decision. You will work closely with the engineering, operations, and service teams and will want to be confident in your choices. Working together can produce a successful high-quality product to meet all business needs. Speed to issue resolution is critical for customer satisfaction, and commercial success, and with FDA approval. An experienced provider can effectively assist through this crucial process.

Here are additional tips and paths to take when choosing an EMS partner:

- Get referrals from other businesses in your industry.

- Use relevant social networks such as LinkedIn.

- Speak to fellow businesses in the industry.

- Attend tradeshows.

- Visit the EMS partner’s facilities and meet with their management team.

- Meeting face-to-face is a great networking tool and visually conceptualizing the production environment is incredibly helpful.

- Ask for references and check them carefully.

- This is similar to a hiring process.

- Build a strong relationship with your EMS partner.

- This will help ensure your projects are completed on time and to your satisfaction.

Collaborating with a contract manufacturer during lifecycle management enhances the efficiency of the end-to-end process, from idea to fulfillment. Outsourcing production can come with risks, which is why it is important to find experienced partners and avoid quality control issues as well as communication barriers. Before making your decision final ensure the selected manufacturing partner has the technical capabilities, capacity, facilities, and a robust operating system to provide the services desired. Also, assess the EMS provider’s willingness and capacity to scale systems, utilities, and processes to meet your project’s benchmarks and requirements.

Nortech Systems is your go-to strategic partner for highly tailored and innovative engineering and manufacturing solutions, built on unparalleled quality and performance. Nortech helps customers identify and solve their problems efficiently. Our experience with multiple clients in various market segments allows us to provide unique and valuable perspectives on the customer’s market while educating them on new risks and issues potentially affecting their business. Our highly equipped global manufacturing facilities allow us to customize and scale our services to meet changes in demand.