Addressing the Need for a New Solution

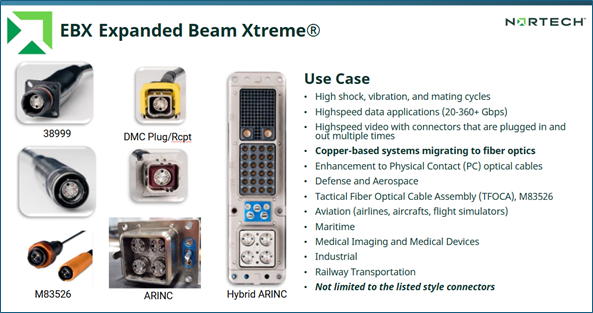

In 2024, Nortech announced Expanded Beam Xtreme® as an expansion of its fiber‑optic capabilities. Our Expanded Beam Xtreme® program is a direct response to our customer’s need: cost reduction. Our engineers challenged themselves to develop a solution that not only lowered cost but also delivered better performance compared to existing copper-based systems our customers were used to, leading our engineers to fiber optics.

Fiber optic connectivity offers the potential to reduce both cost and weight significantly. This technology provides a robust and efficient alternative, particularly for applications requiring frequent mating and un-mating of connectors.

Understanding Expanded Beam Fiber Optic Connectivity

Expanded beam technology is a non-contact form of fiber optic connectivity. Unlike traditional connectors that require precise physical contact between fiber end-faces, expanded beam systems transmit optical signals through the air.

Light from a fiber optic cable enters a connector and passes through a specialized lens that expands the light beam and transmits it across a small air gap to a corresponding lens in the receiving connector. Because there is no physical contact between the lenses, the system is resilient to wear and tear, as well as contaminants like dust and moisture.

Unlike physical contact interfaces, which are typically rated for fewer than 100 mating cycles and suffer optical performance degradation due to wear, movement, or contamination, expanded beam interfaces are durable solutions for applications requiring frequent mating cycles in dynamic or contaminated environments.

The Patented Nortech Advantage in Fiber Optic Connectivity

While expanded beam technology itself is not new, its application in certain systems has been limited. Which is why Nortech has developed and patented a spring-mounted design that allows a wider range of applications to leverage the benefits of this advanced fiber optic connectivity. Ensuring optimal alignment and engagement of the connectors, even in environments subject to vibration and shock.

Our approach to cable design prioritizes reliable performance. This means we focus on three critical metrics:

- Reducing Insertion Loss: Minimizing the amount of lost signal power as it passes through the connection.

- Minimizing Reflected Loss: Reducing the amount of light that is reflected back toward the source, which can disrupt system performance.

- Ensuring Ruggedization: Matching the physical durability of the cable assembly to the specific environmental and mechanical demands of the application.

By optimizing these factors, we deliver high-performance, and reliable interconnects that are also engineered for manufacturability. This approach ensures that our customers receive a fiber optic connectivity solution that is ruggedized for critical applications

Solving Key Customer Pain Points with Fiber Optics

The EBX program also addresses two of the most significant challenges our customers face: weight and electromagnetic interference (EMI).

- Weight Reduction: In industries like aerospace & defense, weight is a critical design parameter. Every gram saved translates into improved fuel efficiency, increased payload capacity, or enhanced maneuverability. By replacing heavy copper cabling with lightweight fiber optics, EBX offers a substantial weight reduction without compromising signal integrity. This provides a significant competitive advantage for aircraft, drones and other critical applications .

- EMI Shielding: Copper cables are susceptible to electromagnetic interference, which can corrupt data signals and degrade system performance. Shielding against EMI adds weight, cost, and complexity. Fiber optics, on the other hand, are inherently immune to EMI because they transmit data using light instead of electrical currents. This benefit of fiber optic connectivity eliminates the need for bulky shielding, further reducing weight and simplifying system design.

The Future of Fiber Optic Connectivity

Expanded Beam Xtreme technology marks a milestone in our long history working with interconnect systems. We have only just begun to explore the full range of applications where these hybrid and parallel fiber optic systems can make an impact. From next-generation aerospace and defense platforms to advanced industrial automation and high-speed data centers, the potential for advanced fiber optic connectivity is vast.

Nortech’s expertise in cabling and harnessing, combined with our innovative engineering and precision manufacturing processes, has poised us to help our customers navigate their data and power challenges by providing connectivity solutions that are lighter, more reliable, and more powerful than ever before.