As technology advances and the popularity of data-centric applications such as machine vision, factory automation, and robotics increases. The need for fast, reliable data generated by powered devices in distant locations is now becoming a necessity more than ever before. Unlike copper cables, limited by their conductivity and data over short distances, smart fiber optic cables use light to transmit data. This characteristic alone makes them the ideal choice since they are not hindered by distance.

Ready to Learn More About Our AOX Cables?

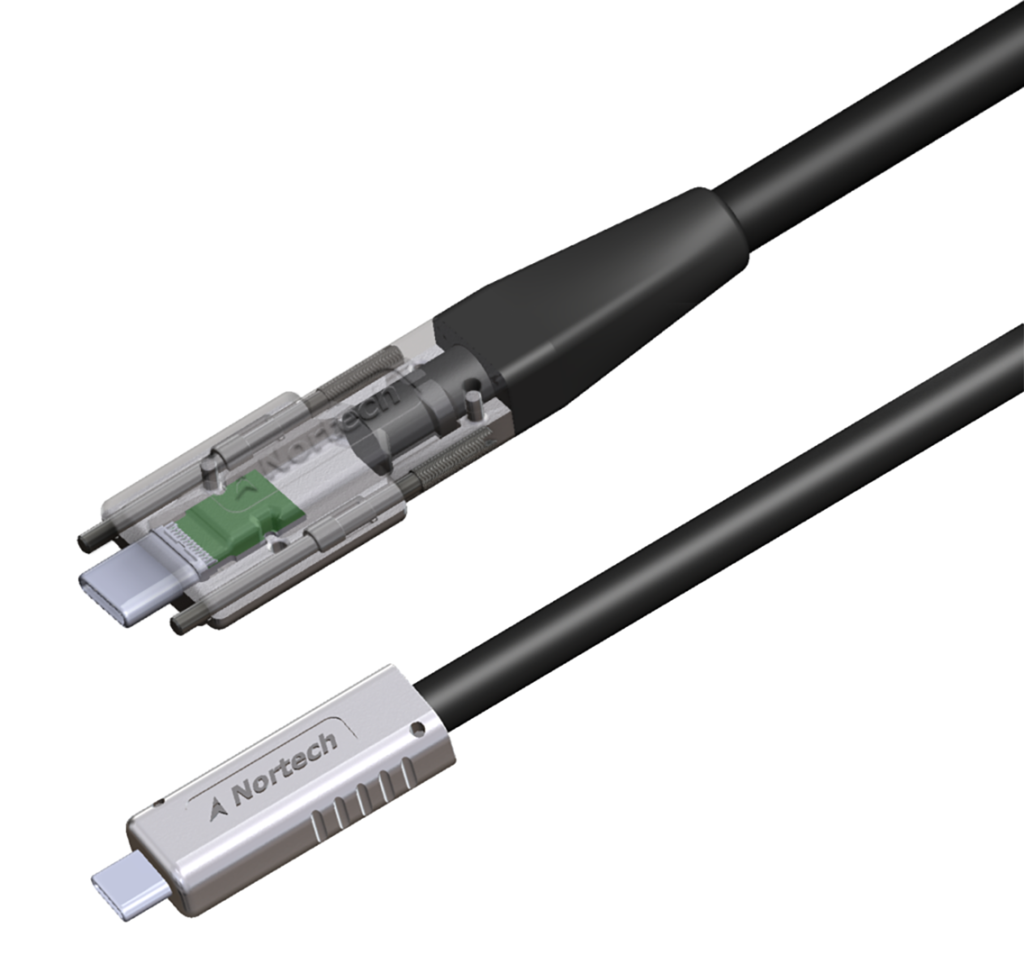

Active optical cables (AOCs) convert electrical signals into optical signals for data and video transmission. This provides greater bandwidth than copper cables while also being thinner, faster, lighter and more flexible. These qualities make our smart fiber optic cables perfect for intelligent sensing devices and vision applications where reliability and speed are key. AOC offers all the advantages of optical fiber without the hassle of fiber termination.

The ruggedized version of AOCs maintains a focus on reliability for challenging environments. Features like high duty & mating cycles, tether pull strength, torsional & rolling flex cycles, shock & vibration and EMI/EMC are critical to a robust interconnect system.

It’s no secret USB-C connectors are quickly becoming the industry standard for many architectures and protocols. Hybrid active optical USB-C power delivery cables are becoming increasingly popular because they deliver significant power and data over distance.

How does active optical USB-C power delivery work? What are its applications in industrial automation and machine vision? Blow, we will dive deeper into this exciting technology.

Active Optical vs Traditional Copper Approach

Hybrid active optical USB-C power delivery cables are a fast and efficient way to deliver power and reliable data.

An AOC utilizes smart fiber optic cables to transmit fast and stable data across nearly unlimited distances. This is all with a much smaller footprint than a historical copper-based approach. Copper-based typically uses multiple shielded copper wires and cables. It’s usually over restricted lengths to support a comparable data bandwidth with marginal data integrity.

The combination of optical fiber and copper wire increases performance speeds. Additionally, it reduces multiple copper cables to a single hybrid cable for power, control and data while preserving compatibility with existing electrical designs.

Benefits of Smart Fiber Optic Cables Compared to Copper

- Smaller

- Lighter

- Faster Data

- Far Superior Data Integrity

- EMI/EMS Immunity

- Highly Ruggedized and Flexible Options

- ‘Greener’ Technology Supporting Rapidly Growing Global Focus on ESG (Environmental, Social, and Governance standards)

Interconnections and cable assemblies are an integral part of any machine vision or factory automation design. Hybrid cable technology incorporating fiber optics offers high bandwidth and integrated power delivery in a single small cable assembly.

Machine Vision Applications

Machine vision is a technology that uses cameras, software algorithms and other processing hardware. It generates rapidly increasing amounts of video and still imagery for real-time analysis.

Vision systems are used in a variety of industries like automotive, semiconductor and electronics to inspect products for quality and defects. Other common uses include remote collaboration, human safety, security, target identification, automated sorting, measurement, process optimization and documentation.

Machine vision systems require high-speed data transfer with power and control to function efficiently in electrically ‘noisy’ environments. USB-C active optical with power delivery offers high-speed data, power and control in a consolidated cable. Transmitting data over fiber optics offers inherent EMI and EMS immunity. Utilizing fiber optics within a shielded hybrid cable assembly enhances data quality to create the superior choice for machine vision applications.

Machine vision applications employing Nortech’s Active Optical Xtreme (AOXTM) cables with a single, hybrid design, have achieved installed lengths of 30 meters and greater. The capability of fiber optics within these hybrids eliminates the cost and complexity of adding Hubs, Retimers and Redrivers to your data path.

Not only are machine vision and imaging applications more diverse but they demand more data, longer distances, greater reliability, simplified interconnect architecture (smaller, lighter, faster), all at a lower cost. This growth leads to a need for video, data and power optimization. We solve it by employing hybrid fiber optic solutions.

Factory Automation Applications

The Industrial Internet of Things (IIoT) integrates physical devices and machines to better monitor and control industrial processes. This is accomplished with sensors and software.

It’s a vital part of Industry 4.0 and the fourth industrial revolution. Characteristics of this revolution include the convergence of technologies like big data, artificial intelligence and the Industrial Internet of Things. IIoT uses actuators and smart sensors to improve communication and collaboration between machines, humans and suppliers.

Smart factories are equipped with IIoT technologies to enable a hyperflexible, adaptive and intelligent production process. This allows for more efficient, interconnected manufacturing processes that can better adapt to changing conditions.

An active optical USB-C power delivery cable is perfect for industrial automation and machine vision systems. The high bandwidth, long-distance capabilities and extremely low Bit Error Rate make it ideal. Reliable and fast data transmission is now more crucial than ever as factories become increasingly automated.

New hybrid cable technology is replacing the need for separate data, power, and control cables. As a result, it streamlines existing transmission methods and allows for continued implementation of IIoT automation and big data.

“We need a hybrid cable that delivers data stability in our noisy EMI environment. Nortech’s cable is our best choice."

#NortechSystems #FiberOptic

“Connector and cable strength were key requirements. Nortech’s ruggedized connector housings met all our needs.” #NortechSystems #FiberOptic #Rugged

Why Choose Smart Fiber Optic Cables & Power Delivery Cables from Nortech?

Nortech Systems has over 30 years of experience developing high integrity data pipelines. Especially for technically challenging applications in harsh environments. Our commitment to research and development has produced the market’s best Active Optical platform. Nortech’s AOX products offer:

- World Class Data Integrity

- Power and Data Over Extended Distances

- FCC Compliant EMI/EMS Performance

- Small USB-C Form Factor

- Standards Based Technology Roadmap

- Environmental Ruggedization

- High Flex/Torsion Durability

- Application-Centric Custom Solutions

Trust Nortech for Reliable Interconnect Solutions & Integration Services

Navigating the complex world of industrial AOC can be daunting, especially when trying to find the right supplier for your needs. Nortech Systems is a leading full-service electronic engineering and manufacturing services provider. We specialize in developing solutions for complex interconnect and cable assembly challenges.

Our engineers are well versed in IIoT and emerging technologies including high-mix manufacturing and prototyping. Additionally, we are honored to have an outstanding reputation for offering our customers best-in-class quality and service.

Your business deserves the best. Nortech experts can help you develop the best smart fiber optic cables for your application while reducing system complexity. Now, you can have a unique solution that also considers your supply chain.

Contact us today!