Vision and sensor systems are growing so rapidly that they require better, more reliable data transmission. And because of this growth, they need even more across longer distances at faster speeds. What is driving this demand, you ask? Fiber optic cables for smart factories and robotics trends. Everyone is shifting toward smart factories, increased use of robotics and more machine vision applications within those industries.

Current commodity cables are not keeping up with these advancements. Although they may be inexpensive, they are typically limited to transmitting data across no more than 10 meters, have poor reliability, and frequently fail in an industrial environment.

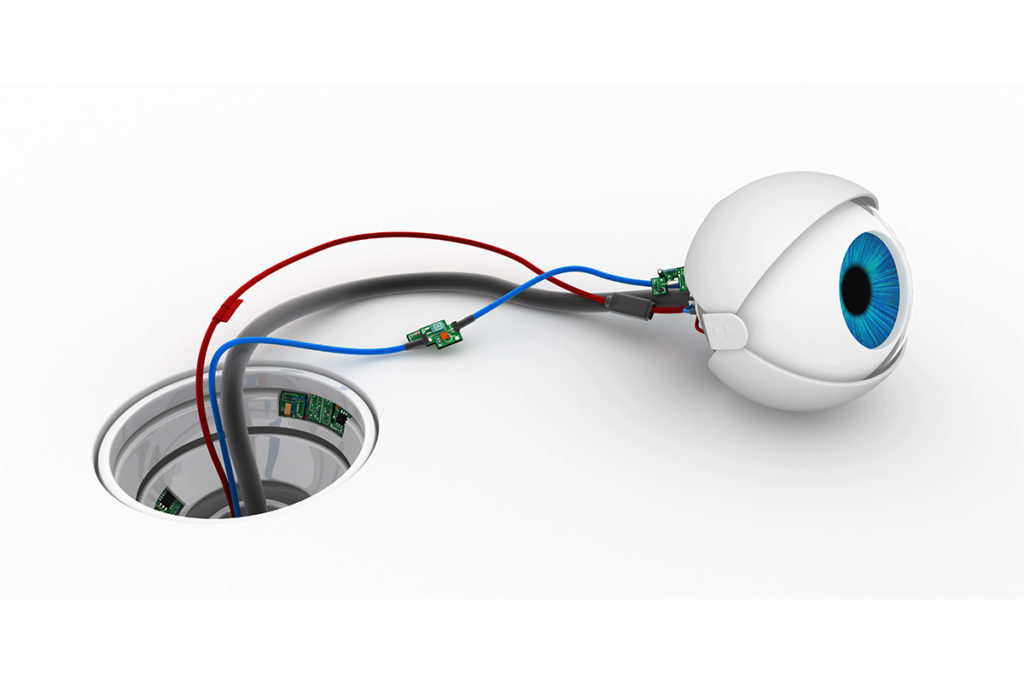

On the other hand, multi-function cables like the hybrid model developed by Nortech Systems, combine copper and fiber with a USB-C connection to form a hybrid active optical data cable. This combination yields a streamlined solution with enhanced power delivery. It’s also specifically designed and tested for rugged environments.

Let’s explore how today’s current manufacturing trends and multi-function cables will meet the rising capability demands below.

Smart Factories

As a result, the adoption of smart factory technologies will continue to grow in the years to come. However, some challenges also need to be addressed, such as increased processing capacity across longer distances with higher reliability.

Current standards limit accurate data transmission across a range of about 10m and require discrete cables for data, control, and power harnessed by a complex connector panel. Multi-function cables provide a hybrid solution with cleaner architecture, unlimited by copper distances.

Robotics Technology

Most robots in manufacturing often conjure images of one-armed machinations welding car parts. However, one of the fastest-growing opportunities is in the area of Robot Process Automation (RPA). This sector is revolutionizing supply chain and logistics by automating manual tasks currently carried out by human workers, like data entry and report generation. RPA is also applied to Enterprise Resource Process (ERP) systems to streamline business processes.

With these robot-connected sensors distributed across the supply chain, production line, warehouses, and distribution centers comes an immense amount of data. All data needs to be transmitted and powered from their remote locations to a potential knowledge center. From there, it’s collected, analyzed, and turned into actionable insights improving productivity and efficiency.

Other new industrial applications include Autonomous Mobile Robots (AMRs). This includes delivery drones and automated picking/packing and material handling robots. Then, of course, there’s the question of who or what is taking care of all these robots. You guessed it, more robots are designed to perform their own diagnostics using more sensors and data analysis. Features like this help to determine when they need to be taken out of service for maintenance.

The data and power cables needed for these fiber optic cables for smart factories and robotics trends applications also need to account for the rugged mobility proficiencies. These are things they will need to possess in the physical environments they will endure. Power and data supplies under these conditions need to handle potentially dusty and dirty atmospheres, support more weight, and potentially millions of rolling or torsional flex movements without failing. Active optical hybrid cables and flexible printed circuitry are currently available data technologies that can meet these challenges.

Machine Vision & Multi-Function Cables

Nortech Applications Engineer, Jerome Taylor said, “In almost every factory, you’re seeing the deployment of more camera systems for monitoring, more sensors, and more and more data collection.” He continued, “Machine vision cameras have gone from one megapixel to 12 megapixels, and the frame rates have increased from 30 to 60 to 120 frames per second.” This is indicative of the increase in data quantity and the speed that it needs to be reliably transmitted.

The medical field has expanded its use of trending fiber optic cables for smart factories and robotics as well. Camera systems are being introduced into the operating theatre providing displays of the procedural area locally and engaging other surgeons off-site. Some health facilities even mount cameras on a patient’s head during an MRI. If that patient moves, the movement can be accounted for, resulting in enhanced image quality.

Augmented reality as a result of machine vision is another example of the growing number of applications in the healthcare field. One example is a system designed to detect the heat signature of blood flow and highlight it on a patient’s arm, making injection administration easier. Similarly, cameras, augmented by machine vision, recognize what they see and relay additional information to the healthcare worker in real time.

Your Partner in Fiber Optic Cables for Smart Factories and Robotics

There is a commonality between all the examples above. They need to reliably transmit more data across further distances while taking up less space. Rugged multi-function cables with hybrid power and data delivery in a small form factor will fill this need.

If you’re working with any of these manufacturing trends, contact Nortech Systems. We help our customers meet the next generation of data and power transmission requirements without today’s current space and distance limitations. Talk to a Nortech representative now!