Wearable medical devices have evolved from simple fitness trackers to sophisticated diagnostic tools that monitor everything from blood glucose levels to cardiac rhythms. This transformation has been driven by advances in miniaturization, materials science, and circuit design, particularly the development of flexible circuit technology.

As healthcare shifts toward remote monitoring and personalized medicine, medical device manufacturers face mounting pressure to create products that are not only clinically accurate but also comfortable enough for continuous wear. Traditional rigid printed circuit boards (PCBs) simply cannot meet these demands. They’re too bulky, inflexible, and prone to failure when subjected to the constant movement and environmental stresses that wearable devices must endure.

This is where flexible circuit technology becomes essential. By enabling electronics to bend, twist, and conform to the human body, flexible circuits are unlocking new possibilities in wearable healthcare. Among the most advanced solutions available today is Nortech’s Flex Faraday Xtreme, which combines exceptional durability with EMI shielding capabilities specifically designed for demanding medical applications.

What Are Flexible Circuits and Why Do They Matter?

Flexible circuits, also known as flex circuits or flexible printed circuits (FPCs), are electronic interconnects manufactured using flexible substrate materials rather than rigid fiberglass boards. These circuits can bend, fold, and flex repeatedly without losing electrical connectivity or structural integrity.

The key characteristics that set flexible circuits apart include their ability to conform to three-dimensional shapes, their lightweight construction, and their resistance to vibration and mechanical stress. Unlike traditional rigid PCBs that require bulky connectors and cables to link different components, flexible circuits can eliminate these connection points by directly integrating multiple circuit sections into a single, continuous design.

For medical applications, these advantages translate into devices that can move naturally with the patient’s body while maintaining reliable electronic performance. This flexibility enables manufacturers to create wearable devices that patients can comfortably wear for extended periods, leading to better compliance and more accurate long-term monitoring data.

Meet Flex Faraday Xtreme

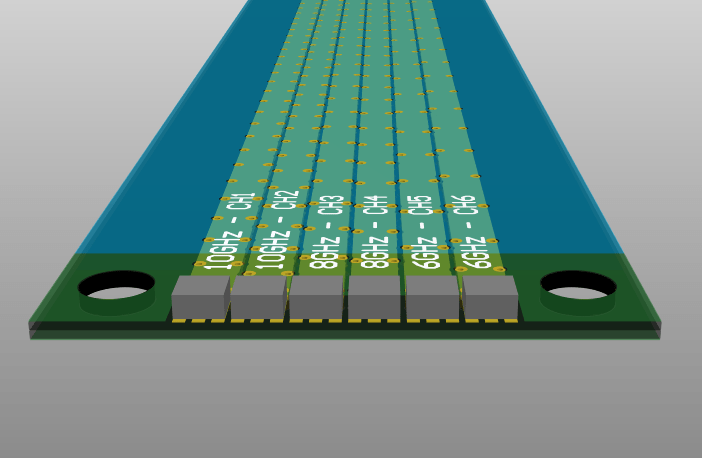

Nortech’s Flex Faraday Xtreme represents a significant advancement in flexible circuit technology, specifically engineered to meet the rigorous demands of medical device applications. This innovative solution combines the flexibility of traditional flex circuits with enhanced durability and electromagnetic interference (EMI) shielding capabilities.

The product’s unique features include extreme durability in harsh environments, making it ideal for devices that must withstand repeated sterilization cycles, exposure to bodily fluids, and constant mechanical stress. Its built-in EMI shielding capabilities ensure signal integrity even in electromagnetically noisy environments, which is crucial for sensitive medical measurements.

Despite its robust construction, Flex Faraday Xtreme maintains an ultra-thin profile that doesn’t compromise the sleek, unobtrusive design that patients expect from modern wearable devices. The technology also offers exceptional design flexibility, allowing manufacturers to create circuits that fit complex geometries and tight spaces that would be impossible with rigid alternatives.

Applications in Wearable Medical Devices

- Continuous Glucose Monitors

Continuous glucose monitors (CGMs) represent one of the most successful applications of flexible circuit technology in healthcare. These devices must adhere closely to the skin while housing sensitive sensors, wireless communication components, and power management systems. Flexible circuits enable CGMs to maintain this intimate contact with the skin while accommodating the natural movement and deformation that occurs during daily activities.

The conformable nature of flexible circuits also allows for more accurate sensor readings by maintaining consistent contact between the device and the patient’s skin, reducing measurement artifacts caused by air gaps or mechanical stress. - Wearable ECG/EKG Monitors

Cardiac monitoring devices benefit significantly from flexible circuit technology’s ability to maintain signal integrity while conforming to the chest wall’s natural contours. Traditional rigid circuits can create pressure points and signal distortions that compromise measurement accuracy. Flexible circuits eliminate these issues while providing the EMI shielding necessary to filter out electrical noise from the environment and other electronic devices.

- Smart Patches and Biosensors

The integration of multiple functions into a single, patch-like device represents the frontier of wearable medical technology. These smart patches can simultaneously monitor multiple physiological parameters, deliver medications through embedded pumps, and communicate wirelessly with healthcare providers. Flexible circuits make this integration possible by providing a platform that can accommodate sensors, antennas, microprocessors, and power systems within a single, skin-conforming package. - Rehabilitation and Mobility Aids

Flexible circuits are also finding applications in more complex medical devices such as powered exoskeletons and smart braces used in rehabilitation medicine. These devices require electronics that can withstand repeated flexing cycles while maintaining reliable performance. The durability and flexibility of advanced flex circuit solutions enable the integration of sensors, actuators, and control systems directly into the mechanical structure of these aids.

Advantages for Medical Device Manufacturers

The adoption of flexible circuit technology offers medical device manufacturers several key advantages that extend beyond the obvious benefits of flexibility and durability. The design freedom provided by flexible circuits enables faster prototyping cycles, allowing engineers to test and refine concepts more quickly than would be possible with rigid alternatives.

This flexibility also translates into improved patient comfort and compliance. Devices that move naturally with the body are more likely to be worn consistently, leading to better clinical outcomes and more comprehensive monitoring data. The enhanced reliability and longevity of modern flexible circuits also reduce warranty costs and improve patient satisfaction.

From a manufacturing perspective, flexible circuits can simplify assembly processes by eliminating the need for multiple connectors and reducing the overall component count. This streamlining often results in lower production costs and improved manufacturing yields, particularly for high-volume products.

Real-World Impact and Future Outlook

The healthcare industry is experiencing a fundamental shift toward remote patient monitoring and personalized medicine. This transformation has been accelerated by recent global health challenges and changing patient expectations for convenient, at-home care options. Flexible circuit technology plays a crucial role in enabling this shift by making continuous monitoring devices practical and acceptable for everyday use.

Advanced flexible circuits like Flex Faraday Xtreme are particularly well-positioned to support innovation in telehealth and home care applications. Their combination of durability, signal integrity, and design flexibility enables the creation of sophisticated monitoring devices that can reliably transmit critical health data from patients’ homes to healthcare providers.

Looking ahead, the integration of artificial intelligence and Internet of Things (IoT) capabilities into wearable medical devices will place even greater demands on circuit technology. The ability to process more data locally while maintaining wireless connectivity will require circuits that can accommodate more complex electronics without sacrificing the comfort and wearability that patients demand.

Enabling the Future of Healthcare Technology

Flexible circuits are fundamentally changing what’s possible in wearable medical device design. By enabling electronics to move naturally with the human body while maintaining exceptional reliability and signal integrity, this technology is removing traditional barriers to continuous health monitoring.

Nortech’s commitment to advancing medical technology through innovative solutions like Flex Faraday Xtreme demonstrates the critical role that specialized circuit technology plays in healthcare innovation. As the demand for more sophisticated, comfortable, and reliable wearable medical devices continues to grow, flexible circuit technology will remain at the forefront of this transformation.

For medical device manufacturers looking to develop next-generation wearable products, partnering with experienced flexible circuit specialists can accelerate development timelines and ensure optimal performance. Contact Nortech to explore how custom flexible circuit solutions can support your innovation goals and help bring breakthrough medical devices to market.