Nortech understands the extreme environments your components will be subject to and the challenges that come with mission-critical aerospace and defense applications. Whether for aircraft, military equipment, marine vessel, or satellite, we continually push the boundaries of engineering and manufacturing to provide our customers with the highest quality products and services. We always know whom we’re working for and helping to protect.

Nortech Systems is AS9100 and ISO 9001-certified, ITAR compliant, and meets MIL-STD-810 Test Standards. We are a multi-disciplinary engineering and manufacturing firm delivering cable assembly and PCBA solutions for global aerospace and defense applications.

Start with a team that excels at selecting materials that can withstand harsh operating conditions. We work with your team to tailor your model, so it meets your specs and is optimized for manufacturability.

We provide engineering services for tooling, testing, and making the right cable and PCB assemblies for the right environment. All engineered to help survive any necessary NBC requirements. Additional services include CAD and mechanical, electrical, and software engineering.

Our tests are designed to simulate the most severe conditions products may face in aerospace and defense applications, such as extreme temperatures, salt spray, abrasion, water and chemical immersions, and EMI interference. Some of our PCBA test capabilities include functional testing, flying probe, and automated test platforms.

We have a flexible yet robust quality management system that ensures our products and services meet customer specifications and exceed their expectations for all quality workmanship requirements.

For decades, we have partnered with every major defense contractor, large and small, to build electromechanical assemblies that will withstand extreme temperatures, pressures, and other stressors found in environments ranging from frozen tundra to scorching desert to saltwater oceans to the absolute zero vacuum of space.

We’ve been a reliable and consistent manufacturing partner for many of the world’s most demanding aerospace and defense applications. You will find our quality cable and PCB assemblies within premier DoD programs. We’re a trusted name because we deliver on our promises and always put our customers first. When you choose Nortech, you’re choosing a proven partner with a history of success.

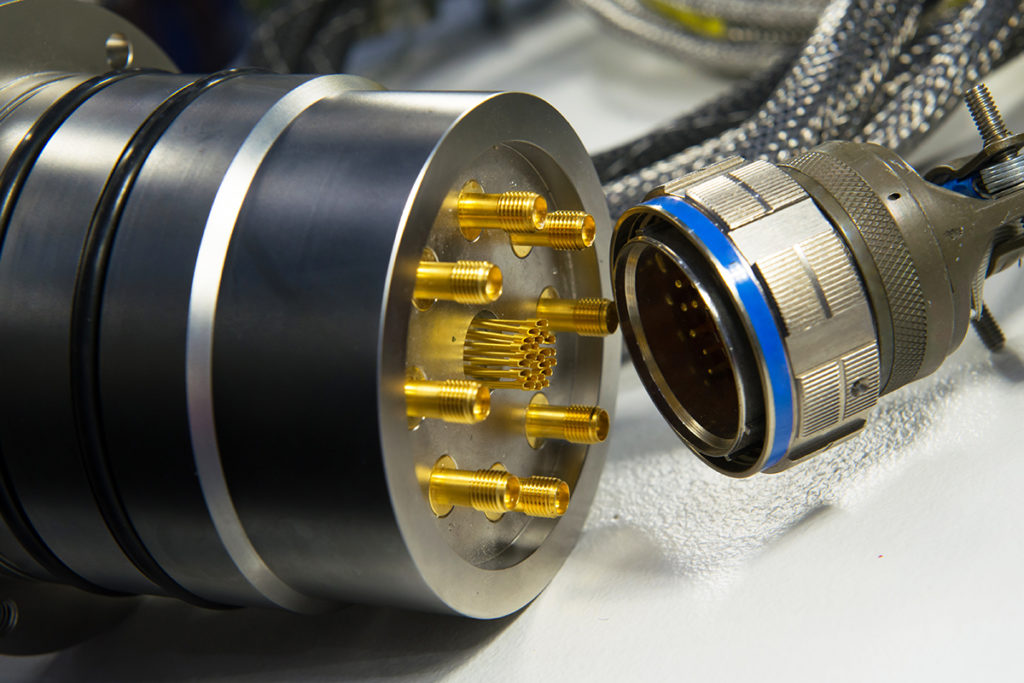

Custom housings, connectors, and feedthroughs require tight tolerances and precision machining requirements. Custom backshells can be designed to incorporate circuit boards, filter arrays, or other electrical components and remain field accessible. We overcome these design and manufacturing challenges with our in-house machining and 3D printing capabilities, which also speed supply chain delivery and reduce cost.

Nortech also provides electrical and fiber termination, including soldering and crimping on almost every type of connector, as well as ESD assembly and custom marking/stamping.

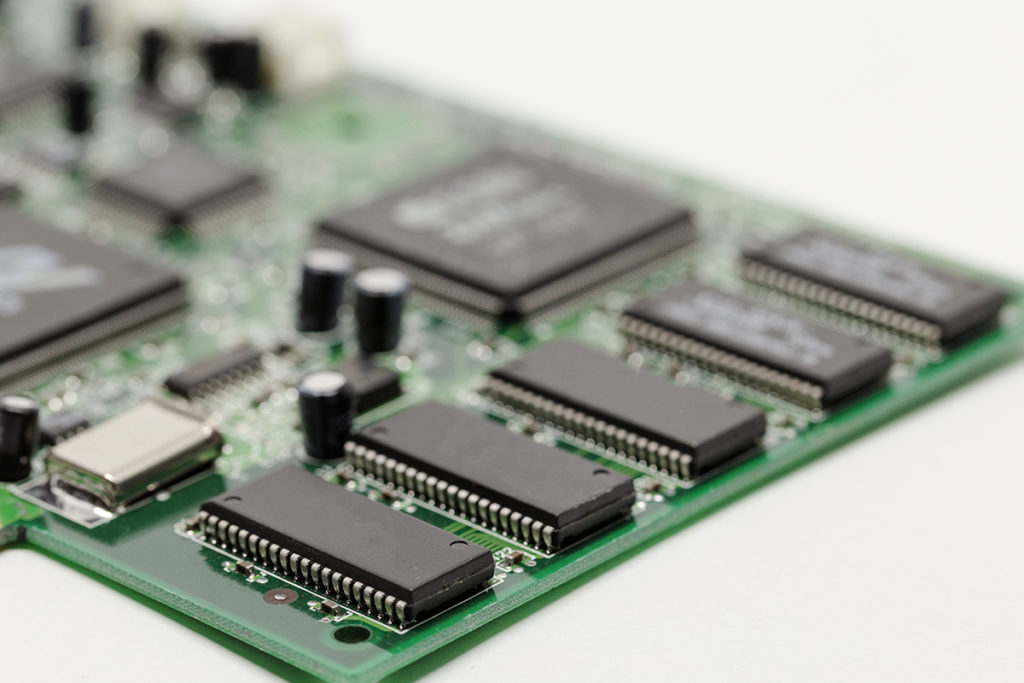

At Nortech Systems, we specialize in designing and manufacturing rugged and reliable Printed Circuit Board Assemblies (PCBAs) ranging from traditional standards to those with state-of-the-art cutting-edge technologies.

Our surface mount technology (SMT) and plated through hole (PTH) lines are fully automated, while our semi-automated through hole line allows us to create customized solutions. We also offer state-of-the-art conformal coating and potting services, functional and flying probe testing, electromechanical high-level box build, and system integration.

Our experienced team will partner with you to create well-defined physical, test, and serviceability requirements that consider the entire product lifecycle. Our wide array of manufacturing technologies allows us to work with any production mix, including low volume/high mix runs. No matter your needs, we have the experience and expertise to get the job done right.

Molded cable assemblies can be created with a few different methodologies, each providing its own benefit. A casted two-part process provides excellent sealing properties as the materials used chemically bond to the backshells and cable jackets. These are chemically cured materials that won’t melt or deform with temperature. These materials can be economically used in very low quantities and can scale up to high quantities using inexpensive tooling.

Moldings can also be created with rubber (elastomer) transfer molding. This process uses uncured rubber, which is pushed into the mold and cured with pressure, temperature and time. Rubber molded cables are designed to be molded to similar rubber jackets (e.g., EPDM to EPDM), which may provide extra dependability.

Lastly, there’s the option of injection molded cables using thermoplastics, which can provide superior aesthetics, including detailing and surface texturing. Thermoplastics can be bonded to other thermoplastics and metals using primers. Injection molding is ideal for high-volume production run rates.

At Nortech, we offer two methods to tool for molded cable assemblies. For most cases, we use traditional metallic-based tools, which would be aluminum for most cases and steel for high-volume designs. These tools are simple to design and inexpensive to manufacture. Additionally, a number of popular circular connector designs may already have tools in place.

For some applications, injection mold tooling may be more appropriate, including many D-Sub and circular connectors. In this variant, aluminum tooling or steel tooling with special inserts can be acquired for a moderate cost. Still, for sub-100 production runs, a 3-D printed mold tool can provide a reasonable cost, a quick turn prototype, and production capabilities. At Nortech, we provide a 3-D printer on-site specifically to support quick-turn mold designs.

Nortech Systems (previously Aerospace Systems) has manufactured cable assemblies for the defense industry for over 50 years. Most products are related to communications, ground support and testing or training applications where rugged environmental stresses and excessive handling conditions warrant the use of extremely rugged assemblies. Some of the major programs produced are:

Actuators Assemblies (UAV, Drones, Aircraft, Missiles)

Abrams Tank M1/A1

ACMI – Air Combat Training POD

ACMI Pod Umbilical

ACMI Pods Internal

Advanced Hawk Eye (AHE)

AEGIS Shipboard

AH-64 – Apache Longbow

AIM 120 AMRAAM

AIM-9L Sidewinder Missile

Aircraft Interface Simulator (AIS)

AMMPS (Power Generators)

Arrow Interceptor Missile

ATFLIR (AN/ASQ-228) Targeting POD

AVCATT Trainer (Helmet)

AWES-MOD Training Simulation

B1B – Lancer Bomber

B-52 – Stratofortress Bomber

BFVS – Bradley Fighting Vehicle Systems

Boeing 777

BQM-74 – Target Drone

BRU-32 – Bomb Ejector Rack

C-130 Hercules

C-17 Globemaster

Command Voice

Crusader Howitzer

DSIU-Radio System

Electric Brake (Aircraft)

Electric Industrial Tools

EMUT Radio System (AN/PSC-5)

ESSM-SeaSparrow Missile

F-14 – Tomcat (Aircraft)

F-15 Strike Eagle (Aircraft)

F-18 – Super Hornet

F-22 Raptor

F-35 JSF Lightining II

F-4 Helmet Gunsight System

F404 Engine

F-5 (Aircraft)

Falcon II Radio System (AN/PRC-150)

Fire Scout UAV (MQ-8)

Global Hawk UAV (RQ-4)

GRC-206 Radio System

Harpoon GSE

Have Quick II Radio System (AN/ARC-164)

Heated Hose Assembly (Dispensing or Robotic)

IHADDS – Helmet Assembly

Industrial Crane Harnesses

Industrial Milling Machines

ITS – Independent Target System

IWS – Individual Weapon System

JASSM Missile

JATO-Jettison Release Mechanism

JLTV Vehicle

JTRS Radio System

Land Warrior – Weapon System

LOSAT (MGM-166)

LRAS3 (Surveillance)

M1114 – (Up-Armored HMMWV)

M-ATV (MRAP All-Terrain Vehicle)

Maverick Missile (AGM-65)

MBMMR (AN/PSC-5D)

MEADS Defense System

MILES 2000 – Training Simulation

MK 105 Mine Detector Sled

MK 46 Torpedo

MK13-MK14 VLS Launcher

MK-41 (Vertical Launch Systems)

MK86 Gun Fire Control System

MK92 Guided Missile Fire Control System

MK95 Fire Control Radar

MK-VII – Laser rangefinder

Mounted Warrior (Helmet and body worn)

MRAP – Mine Resistant Ambush Protected Vehicles

MTS – Movement Tracking Systems

MTS-B (Targeting System)

MULE – Autonomous Vehicle

Patriot Missile (MIM-104)

Paveway (GBU-12) Laser-Guided Bomb

Peacekeeper Missile (LGM-118)

Predator UAV (MQ-1)

Quick Strike Missile

Regency Net Radio System (GRC-215)

Regional Jet

Robotic Shell Loader

SDB II (GBU-53/B) Small Diameter Bomb

Seawolf (SSN) Submarine

Shadowfire – Radio System (AN/PSC-5V)

Shrike Missile Umbilical (AGM-45)

SINCGARS Radio Systems

Small ICBM Missile (MGM-134)

Smart Bomb

Sparc 20 – Mainframe Computer

Spitfire – Radio System (AN/PSC-5)

Striker Vehicle

Titan IV (Payload Rocket)

Tomahawk Missile

TOW II Anti-Tank Missile (BGM-71)

Trident II (SSBN) Submarine

UH-60 – Blackhawk

VIS – Vehicle Intercom System (VIC-3, VIC-5)