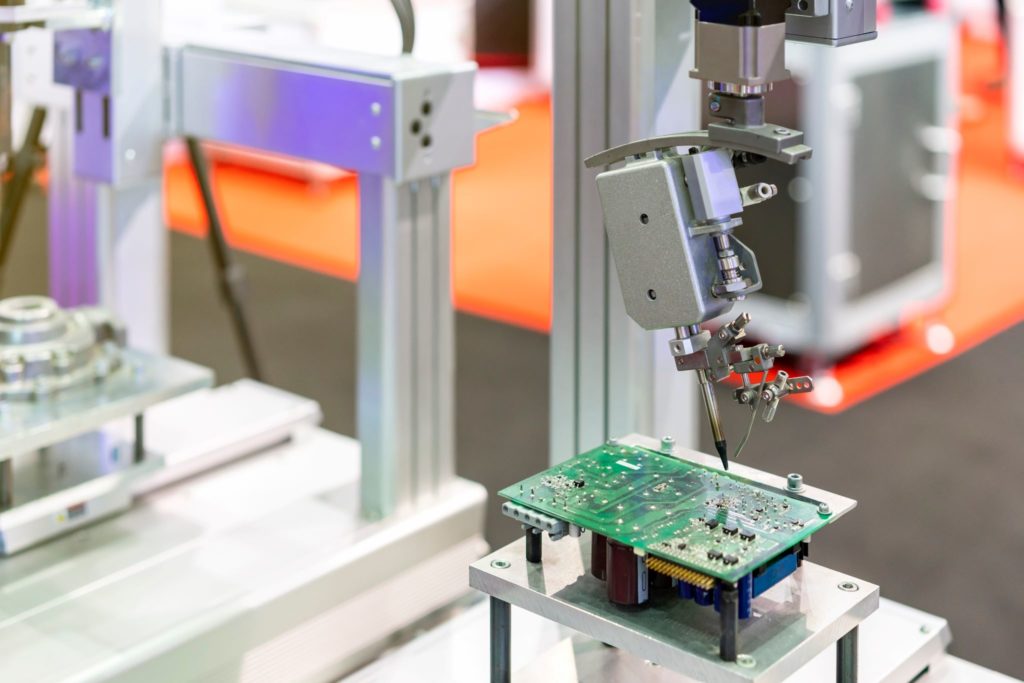

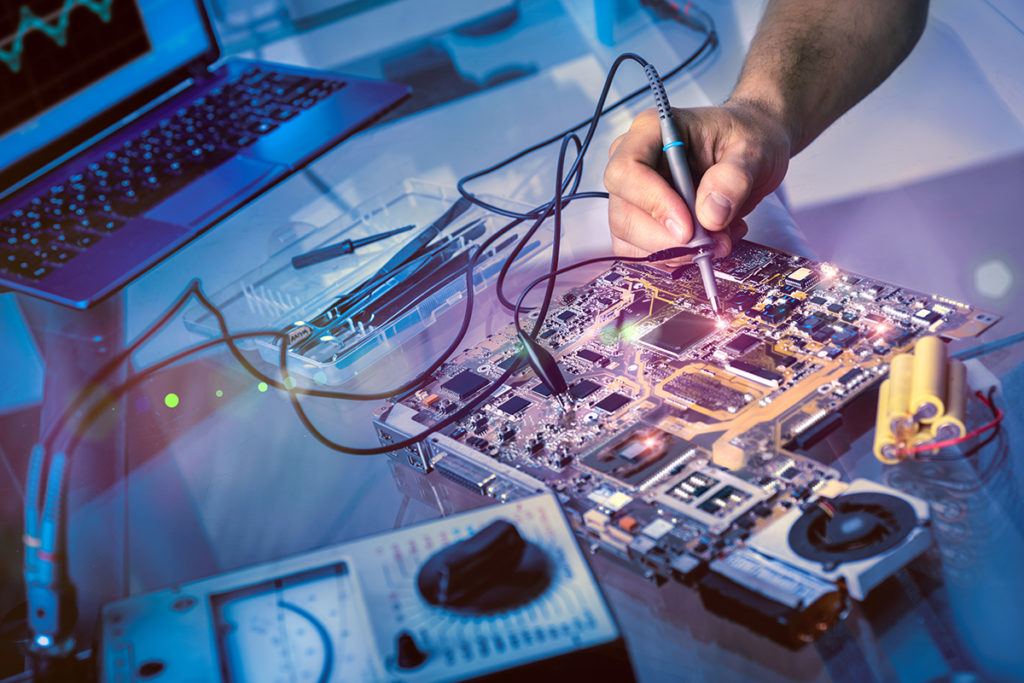

In today’s fast-paced electronics manufacturing landscape, optimizing test processes is paramount to achieving higher yields, reducing costs, and...

Read More »Lifecycle Management

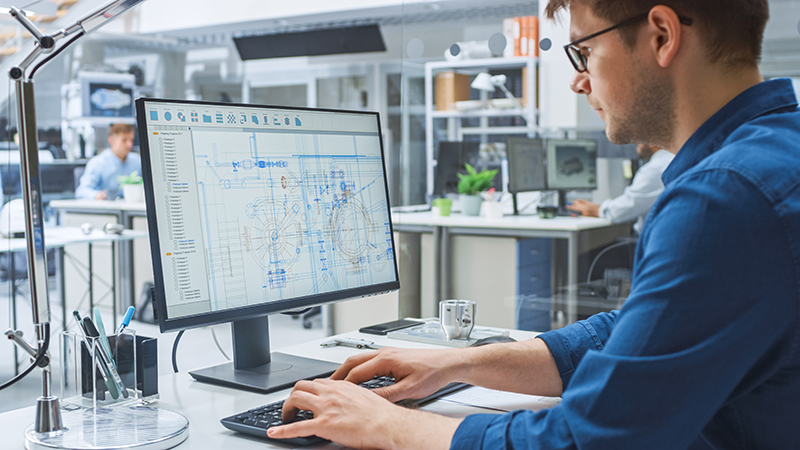

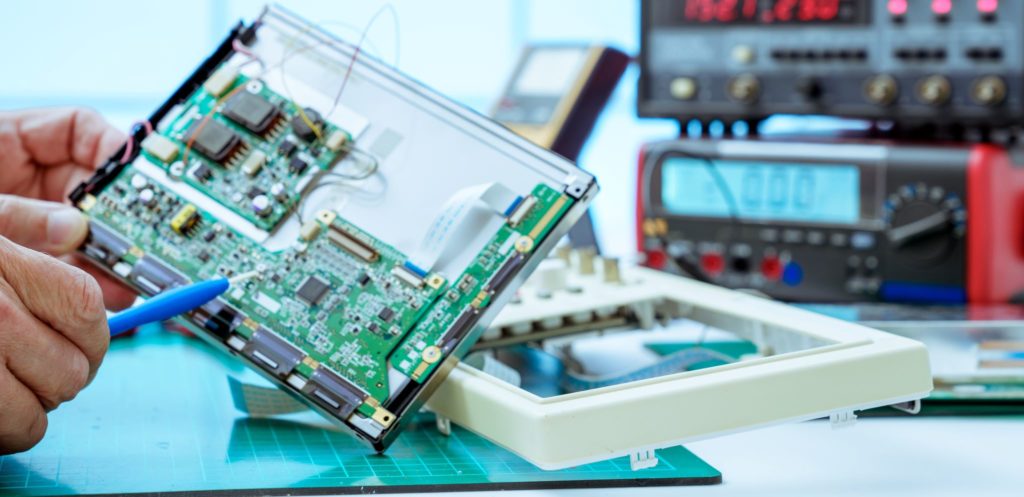

A strategic approach to coordinating communication and resources between concept and design, product launch, inventory planning, postmarket support, and product closeout. We also offer a full range of testing, repair, refurbishment, and postmarket services.

Lifecycle management is essential to research, engineering, and new product development, as it brings program planning, manufacturing, maintenance capabilities, and services together in a unified view. At Nortech, this holistic approach enables engineering teams to ensure that research happens in the context of customer needs and feedback while also producing products with greater efficiency while managing cost, constraints, and customer expectations.