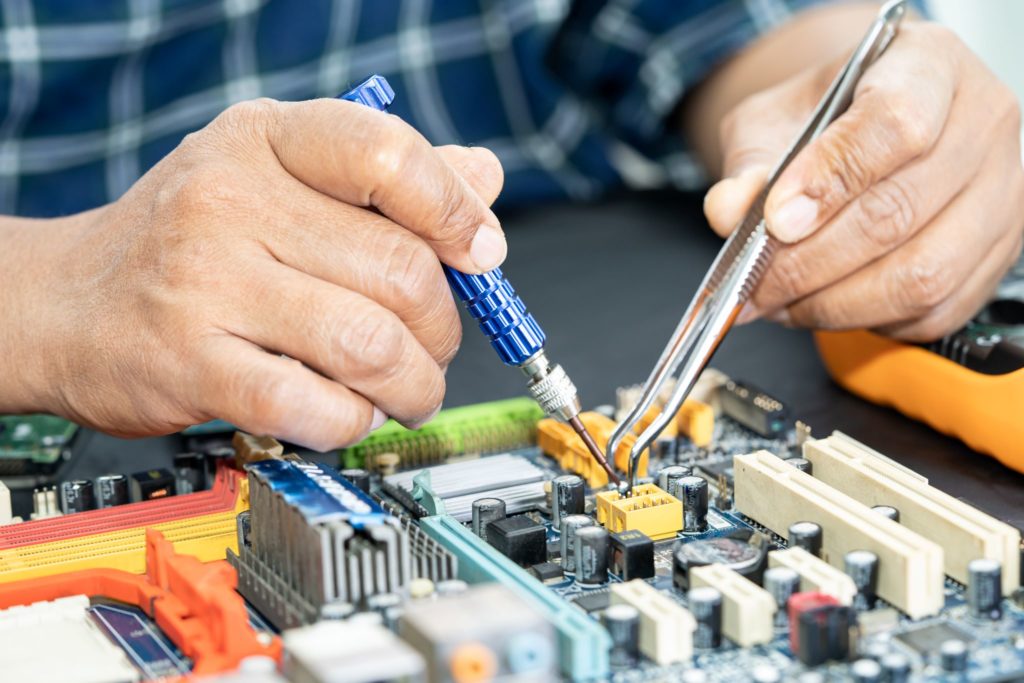

Factors to Consider When Selecting an EMS Partner

Choosing the right Electronics Manufacturing Services (EMS) partner is a critical decision for any company wanting to outsource the manufacturing of cables, PCBAs, and integrated devices. It is more beneficial today than any other time in our industrial history to outsource manufacturing. Faced with limited resources, many companies find it is no longer the best […]

Supply Chain and Fulfillment Solutions

In this video featuring John Lindeen, Sr. Vice President of Global Operations, he shares expert insights on some of the systemic issues companies are facing as they manage supply chain challenges in an efficient and forward-thinking way. John emphasizes the importance of selecting manufacturing partners who align strategically at the management and executive levels. With […]

AI: The Next Evolution of the Information Age in Manufacturing

AI: The Next Evolution of the Information Age in Manufacturing Billions of IIoT devices are spewing out data every day, yet the vast majority of information goes unused. Similar to planting crops but failing to reap them, many existing cables are unable to process all the IoT data, impeding our ability to compile and use […]

Guide to Navigating FDA Regulatory Approval Process

In the U.S, the FDA regulates the sale of medical device products. To gain the FDA’s approval to sell a medical device, businesses must first present evidence of the products safety and effectiveness for its intended use. These regulatory approvals are just a piece of the product launch process but can be hard to manage. […]

Medical Device Engineering, Design and Build

Nortech Systems is a leader in the design, engineering and manufacture of medical device systems. Both our Engineering Design Center in Maple Grove, Minnesota and our Manufacturing Center of Excellence in Milaca, Minnesota are ISO 13485-certified. Our team of program managers and engineers partner with medical device companies to manage the entire lifecycle from initial […]

A Guide to Strategic Supplier Management in New Product Development

Developing a new product is a complex and dynamic process that requires the collaboration of multiple stakeholders, including engineers, designers, suppliers, and regulatory bodies. One key to successful new product development is managing suppliers effectively, ensuring they meet the required quality standards, cost targets, and delivery schedules. This guide will outline five phases of new […]

RoHS and REACH Compliance: Why Are They Important?

What are REACH and RoHS? RoHS (Restriction of Hazardous Substances) is a European Union (EU) directive restricting the use of hazardous substances in electronic products. It was introduced in 2003 to protect human health and the environment from potential harm caused by substances such as lead, mercury, cadmium, and hexavalent chromium. The directive aims to […]

Benefits of a Design for Supply Chain Methodology

If you have been involved in manufacturing anything in recent history, you have been there – you have customer orders waiting, your lines are down, and you are just learning now that your components won’t be available for weeks, or even months, because of supply chain issues. That low-cost custom part could now hold up […]

Supply Chain Risk Management Best Practices

When You Can’t Support Your Customers You may not be the doctor telling the patient that their medical tests and procedures have to be delayed because there aren’t enough supplies on hand. You may not be the operations officer watching your AOG (aircraft on the ground) hours rising out of control, leaving your troops immobilized […]