Process Efficiency Through Generative Data Analytics

In today’s fast-paced electronics manufacturing landscape, optimizing test processes is paramount to achieving higher yields, reducing costs, and accelerating time-to-market. The advent of generative data paired with advanced analytics has ushered in a new era of possibilities for manufacturers. By harnessing the power of these technologies, businesses can gain unprecedented insights into their test and […]

Nortech’s In-House Mold Tooling: 3D Printed Prototypes

In an era where speed, efficiency, and innovation are paramount, the ability to design and manufacture mold tooling in-house is a game-changer for engineers at Nortech and industries worldwide. By harnessing the power of 3D printed prototypes and advanced machining technologies, manufacturers like Nortech can achieve unprecedented control over their production processes. Faster Lead Times […]

Harmonizing ISO 13485 and FDA Regulations

In the world of medical devices, ensuring patient safety is priority. Regulatory bodies worldwide set stringent guidelines to minimize risks associated with these life-changing technologies. For medical device companies, navigating these regulations can be a challenging, especially when dealing with overlapping standards like ISO 13485 and the US Food and Drug Administration’s (FDA) 21 CFR […]

3D Printed Rapid Prototyping: A Game Changer in Manufacturing

The innovative technology of 3D printed rapid prototyping, or additive manufacturing, is transforming the way Nortech approaches design and prototyping. Offering a faster, more cost-effective, and versatile solution compared to traditional methods. 3D printing is the construction of a three-dimensional object from a CAD model. Traditionally, creating prototypes involved a lengthy process of outsourcing to […]

Using Fiber Sensors to Engineer Prescriptive Maintenance

From Reactive to Proactive The Future of Manufacturing with Fiber Optic Sensors The manufacturing landscape is undergoing a digital transformation, and fiber optic sensors are at the forefront. Embedded within machinery, robotics, and dynamic electro-mechanical systems, fiber optic sensors are lightweight, space-saving, and electrically transparent. Fiber sensors are commonly used to detect subtle environmental changes […]

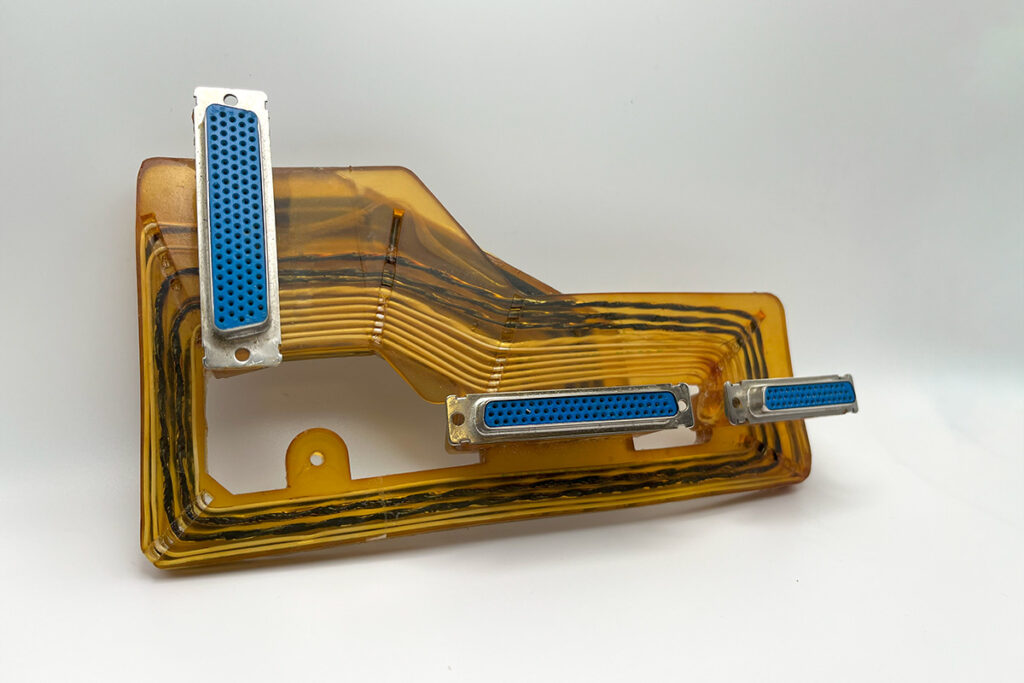

Flat Cable Solutions: Integrating Shielding and Reliability

Flat Cable Solutions: Integrating Shielding and Reliability As our world continually demands smaller, faster, and more powerful electronic systems, the anchoring components within these innovations must evolve in kind. For electronics engineers working within the aerospace and defense industry, the integration of flat cable solutions is an important component of the overall design. These flat, […]

Ruggedization of Expanded Beam Fiber Optic Cables

Nortech Systems recently announced an expansion of its fiber optic capabilities with the launch of Expanded Beam XtremeTM (EBXTM), a ruggedized and highly customizable platform of fiber optic solutions. Expanded beam fiber optic connectors use a larger beam diameter than a physical contact interface. The oversized light beam used in a lensed connection provides increased […]

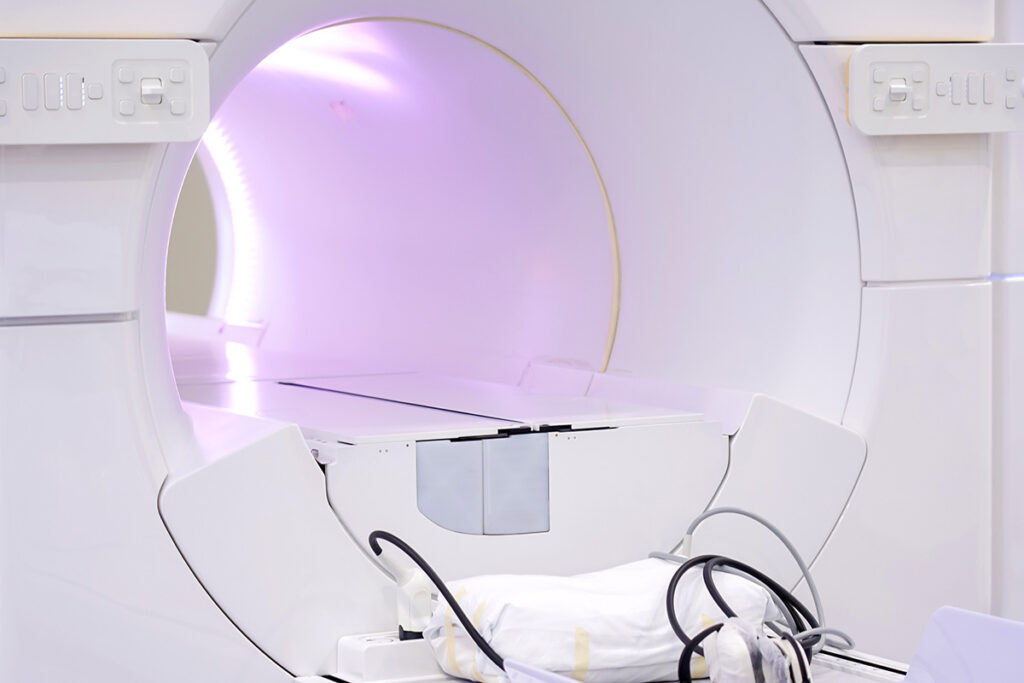

Innovative Medical Technology Keeping Patients Safe

Are accessory projects consuming your team’s bandwidth leading to inefficiency and higher development costs? Or is a standalone development project outside your team’s field of expertise causing delays to product launch? That is what a Nortech client was experiencing when developing a new system for patient monitoring in a hospital setting. Innovation For Medical Technology […]

Mitigating Risks With White Room and Clean Room Facilities

In the world of electronics manufacturing, both white rooms and clean rooms play crucial roles, serving different purposes and following distinct standards. A white room is primarily designed to control factors like temperature, humidity, and dust. These environmental controls ensure the protection of sensitive electronic components during assembly and reworking processes. Clean rooms take it […]